Until the late 1970s to early 1980s blow molding machines were primarily delivered with contractor control. This type of control offered the advantage that the electrical components could be checked by appropriately trained maintenance personnel and easily replaced in the event of a fault. Changes in the machine control system could be made with the help of simple auxiliary devices. However, the disadvantages were the susceptibility to faults and short service life due to wear of mechanically moving parts, the large number of components (up to 150 contactors, 12 temperature controllers, etc.), the size of the components, and how these elements were connected. This type of control was called “hard-wired programmed logic controller”.

Blog

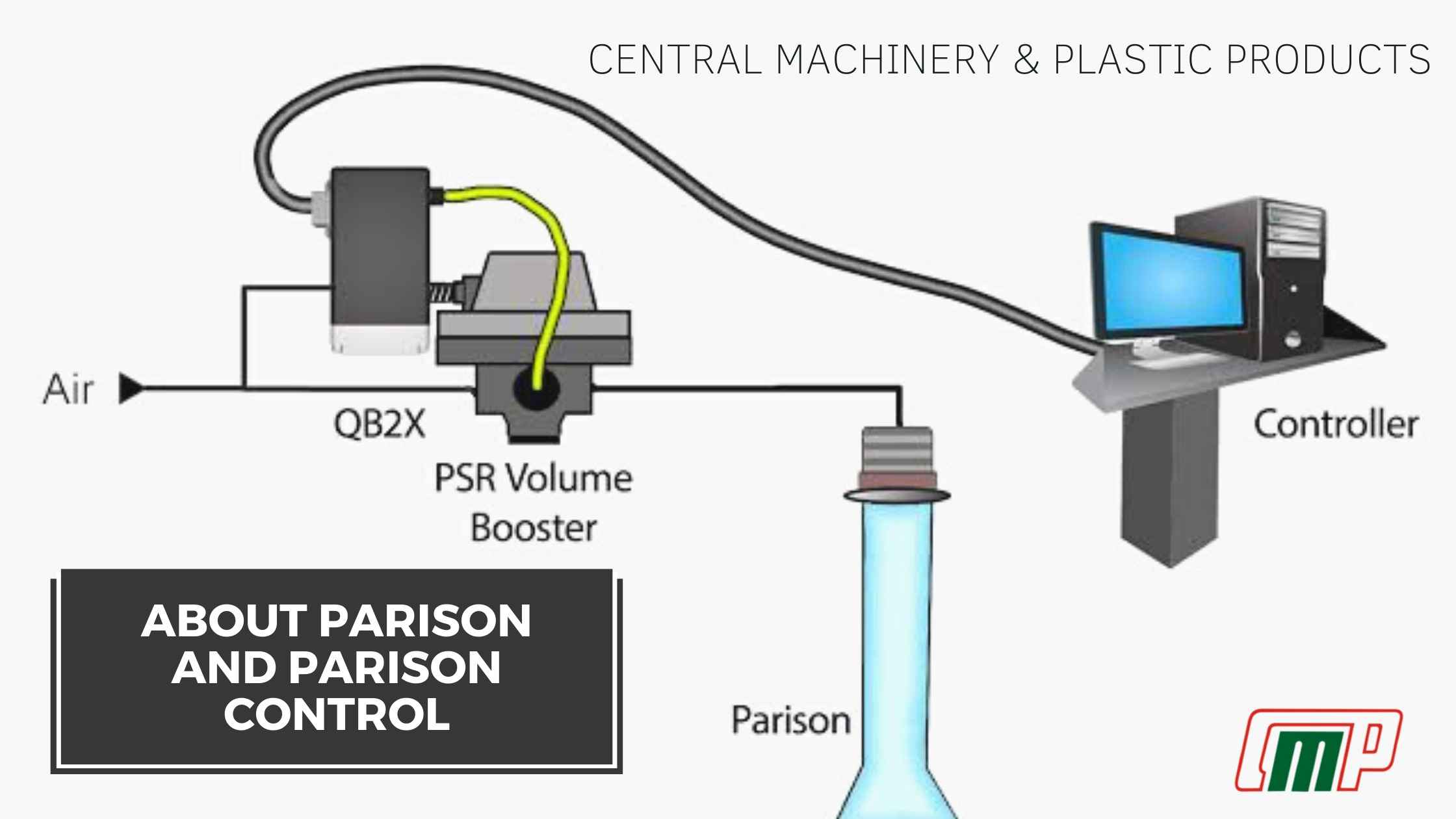

About Parison and Parison Control

Parison blow moulding of intricate plastic bottles and other plastic parts requires air pressure control that is precise, repeatable and rapid responding. Proportion-Air offers electronic closed-loop pressure and flow control used to improve processes in the plastics blow moulding industry.

Once set, the control profile can be saved to a file in the customer’s PLC. A changeover to make a different part becomes as easy as pushing a button. The electronic pressure controllers can be factory-tailored to any application requirements.

We’ve often found that controlling the flow to a parison blow moulding application is more effective, in certain situations. But, if pressure control is to be used, we always specify our 2-loop pressure control configuration featuring a QB2 and volume booster assembly for maximum accuracy and repeatability.

Capturing the Parison

To design a blow moulded product, you must understand the interaction between the molten plastic parison and the mould. If you’ve blown a bubble from bubble gum you can understand blow moulding. The plastic material stretches like the gum and if it gets too thin it ruptures. Since the parison is extruded as a tube, it is easy to make a tube or bottle-shaped part, not much stretching occurs. The two mould halves open, the parison is inserted, the mould halves close and the part is blown. The split between mould halves is known as the parting line. We try to have a large enough parison diameter that as it flattens, it can be captured by the entire perimeter of the panel at the pinch-off. If the parison does not extend to all areas of the pinch-off, it must stretch the rest of the way.

The soft plastic can stretch only a short distance before it begins thinning. Like the bubble gum, the first thin spot is weakest and it gets thinner fastest until it pops. If the plastic parison pops it is called a “blow-out” and results in no part formation at all.

Parison wall thickness control in blow moulding is an important step during the production process. To a certain extent, it improves the quality of blow-moulded products. So, how much do you know about parison wall thickness control in blow moulding?

Why parison wall thickness control in blow moulding is important?

- For blow moulding products:

Blow moulding technology is to make the plasticized parison close to the inner wall of mould by air pressure. Minimum parison wall thickness is specified for the blow moulding container products due to its strength requirements. The parison wall thickness of blow moulding products is also a major factor to measure quality. So, during the production process, to ensure the quality of blow moulding products, it requires the parison wall thickness can accurately track the setting value and the responding speed of tracking is fast enough. The wall thickness of the parison is more uniform and stable, the blow moulding product is more strong and wearable, the quality is better.

So, parison wall thickness control in blow moulding is important.

- Fora plastic blow moulding machine manufacturer:

Now, the customer’s requirements for blow moulding products are becoming more and more diverse, such as different capacities, different shapes, purposes, layers, and so on. The requirement of layers is related to the parison wall thickness. Why? If customers want to produce multi-layers blow moulding products, it involves the uniformity of every layer wall thickness.

Naturally, the technology of parison wall thickness control in blow moulding is needed. The parison wall thickness control is also helpful to improve the performance of plastic blow moulding machinery.

What is Parison wall thickness control in blow moulding? About its principle?

Blow moulding process, the material is extruded from the gap of the die head after plasticizing, moulded by blowing and cooling. The principle of parison wall thickness is heating the expansion equipment at the lateral mould ring of the mould outlet. Adjust expansion equipment temperature by the heater.

By the change of expansion volume at different temperatures, push forward the radial deformation of mould ring, change the size of mould gap, control the outflow at the mould, and change the parison wall thickness.

Generally, there are several thermal expansion equipment installed on the circumference of the mould ring. Control the interfacial gap of the mould at each point on the circumference to achieve the control effect of parison wall thickness in blow moulding.

How to achieve the parison wall thickness control in blow moulding?

There are many control methods for blow moulding machines, right?

For example, profile mould, axial wall thickness control technology and radial wall thickness control technology and flexible ring technology, edge modification technology, embryo temperature difference method, the combination of vacuum suction and extrusion blow moulding, etc.

In addition to these control methods, the corresponding parison wall thickness controller can also be used to cooperate with the blow moulding machine.

The method of parison wall thickness control in the blow moulding machine is different. Dividing several points during the moulding process of each parison. Control the parison wall thickness of these points separately. The fewer the number of control points, the faster the response speed. But, the control points are too few, it’s hard to achieve the accuracy of parison wall thickness control, and form the weld seam around the parison. If there are too many control points, it will cause the responding speed too long. The parison has come out before the servo cylinder can respond to the received signal.

The level of plastic blow moulding processing machines depends largely on the level of control. The blow moulding machine with good performance is a widely adopted control system with high accuracy. Fuzzy control, statistical process control (SPC), and network-based remote monitoring and fault diagnosis control systems are used in some high-precision plastic machinery.

In the long term, whether it is a plastic machinery manufacturer or a user of plastic machinery, parison wall thickness control in blow moulding is a reliable technology to improve the performance of machines or products.

About CMP parison controller for blow moulding.

Over the years of experience and development, CMP blow moulding machines provide parison controllers with BECKHOFF AND B&R Automation. Our parison control is integrated with the machine which results in one PLC control and helps save in power as it works on machine Hydraulic circuit. Other make parison control runs on separate hydraulic circuits which adds on a hydraulic motor which increases the power consumption. CMP parison control has the capability to run 2 different profiles at 2 different stations.

CMP blow moulding machines are equipped with different types of parison controls ranging from 300 to 100 points depending upon the display of selection.

CMP also offers portable parison control used when you’re machines are not equipped with a build-in parison controller: https://cmppin.com/product-category/parison-controller/

Blogs

CLAMPING UNITS IN EXTRUSION BLOW MOULDING

In all extrusion blow molding processes, a blow mold consisting of two halves closes around the parison once it has reached its full length. These two halves of the mold are mounted on the so-called mold mounting platens, which from part of the clamping unit (or closing unit).

RADIAL WALL THICKNESS DISTRIBUTION IN BLOW MOULDING

In blow moulding, the wall thickness distribution of the finished article is essentially determined by the wall thickness distribution of the parison, its position in relation to the blow mould cavities, and the local stretching paths.

SWELLING BEHAVIOUR OF THE PARISON

The visco – elastic behavior of the thermoplastics (here the memory effects) in conjunction with the flow channel geometry in the head causes the diameter of the parison to change after leaving the die. The wall thickness also changes and thus the length of the parison. This phenomenon is called ‘; die swell’’.

MANDREL HEADS IN EBM

In mandrel heads (also referred to as ‘’heart – shaped – curve heads’’, or cardio did heads) the solid core part is massively integrated into the basic structure of the head. These heads are also called side-fed heads.

SPIDER HEADS IN EBM

The main task of parison heads (blow heads or even just heads) is to divert the compact melt flow as supplied by the extruder into a vertical downwards flow movement and to form melt tube with a uniform circumferential wall thickness distribution.

EXTRUDER WITH GROOVED FEED ZONE

Blow moulding machines with grooved barrel extruders are universal machines for all types of polyolefin; the grooved barrel system is,however, indispensable for high molecular weight, high viscosity raw materials. In these extruders, the cylinder wall in the feed section features tapered longitudinal grooves.

SMOOTH BORE EXTRUDER

Blow molding machines with smooth – bore extruders are more or less limited to the processing of low to medium molecular weight polyolefin types. Smooth bore extruders are less expensive than those with a grooved feed zone and show less screw wear.

Is a Blow Molding Machine Used to Make Anything Other than Plastic Bottles?

For manufacturing plastic bottles, experts rely on a state-of-the-art blow molding machine. With this particular process, a manufacturer produces a broad range of finished products in varying sizes and shapes. Because of that, multiple industries depend on a professional company to make a specific type of plastic bottle needed.

What Are the Future Trends of Plastic Molding Machines?

Although the plastic molding industry took a hit this year due to the instability within the automotive industry, it’s still on target for breaking records. After all, the plastic molding machine is something that a broad range of industries rely on for both internal operations and the making of consumer goods. As demand increases, you can expect to see some exciting changes for plastic molding machines.

Can Extrusion Blow Molding Produce Complicated Shapes

When it comes to extrusion blow molding capability, most people think of standard plastic bottles, tight-head containers, jars, and larger water containers. However, the extrusion blow molding process can do much more. In fact, when using a technologically advanced extrusion blow molding machine, it can produce finished products with complicated shapes, and in varying sizes.

Rotational Molding: Advantages and Disadvantages

Rotational moulding offers a number of benefits, but it’s not the best production process for every part. So how do you decide if it’s a fit for you? Understanding the advantages and disadvantages of the process is the first step toward making a decision with confidence.

Importance of Extrusion Blow Moulding Machine in the Pharma Industry

Nowadays plastic is the reliable and most effective form of packaging for different industries and pharmaceutical domains. In the pharmaceutical sector, two types of polymers are used, thermoplastics and thermosets.

HOW TO START A TOY-MAKING BUSINESS WITH EBM IN INDIA?

Before starting the toys making business, it is important to do market research. It is important to collect as much information as possible about this business so that you get the knowledge of exactly what kind of toys are in demand in the market.

WHY INDIAN GOVT. ENCOURAGES TOY MAKING BUSINESSES MAKING BUSINESS

Indian government motivates and urges the Indian startups in the toy sector to maximize manufacturing and increase the reach of Indian made toys to the world. After holding a meeting with senior officials and ministers, the Prime Minister make a statement and urge the start-ups and young blood to innovate in the toy sector. Also, PM has given the suggestion to the educational institutions to arrange competitions in toy technology and design.

Biodegradable vs. Recyclable Plastics

Biodegradable plastics undergo digestion by microbes to form natural bi-products and what is known as humus (a sludge that makes an excellent plant fertiliser). It also produces gas which is officially known as biogas. Biozone’s landfill-biodegradable plastics have proprietary additives that help them biodegrade naturally in landfills. Once the biodegradable packing ends up in a landfill, it attracts the necessary microbes that break down the plastic into its natural components.

The Future of the Extrusion Blow Molding Machine

Everywhere you look, competition among different industries has exploded. Thanks to a thriving market, companies that once struggled now see incredible success. Just as businesses need ways to stay ahead of the competition, so do extrusion blow moulding machine manufacturers. Because of that, they continually push to come up with more innovative solutions.

Why CMP Machines are the BEST?

Innovation is at the heart of any successful company. Innovation keeps an organization at the top of their game, allowing them to flex their competitive muscles and take pride in the work they do.

What is Multilayer Extrusion Blow Moulding Machine?

Nowadays literally all humankind use plastic products 24/7 all over the world. It is super easy to get access to all kinds of plastic products. You might have come across bottles that have a shiny layer on the outer side, or different colours on the outer and a different one in the inner. So, what it is? It is a multilayer extrusion product. Well, let me explain to you how what it is exactly.

Exterior Surface (Mold Cavity) Design

The inner and outer walls of the part are formed simultaneously and integrally, but interior and exterior designs are essentially independent so we review them separately. As the design develops, the designer should begin thinking about the interaction of the plastic and the mould that will produce the part. The visual exterior of many products is formed in one half of the mould called a cavity. Following are some of the features of mould cavities the designer will want to consider.

Interior Surface (Mold Core) Design

The inner and outer walls of the part are formed simultaneously and integrally, but interior and exterior designs are essentially independent so we review them separately. As the design develops, the designer should begin thinking about the interaction of the plastic and the mould that will produce the part. The interior surface of double-wall blow moulded parts is normally formed by a mould core. Since the mould core must fit inside the cavity, there should be no question it meets the same core blow ratio = W>2D overall size requirement as the cavity.

Why CMP Blow Moulding Machine?

Multiple industries and outside manufacturing companies depend on advanced extrusion blow moulding machinery. Without the right machine, there would be no way to produce superior quality products and we, at CMP, provide quality over quantity. Let us go through the advantages you will get for using CMP’s machine.

Information about the series of Extrusion Blow Moulding Machines in CMP

Have you ever seen a person at the fair or the mall during the holidays, blowing glass to create beautiful, artistic designs? It’s mesmerizing how a random piece of coloured glass can be manipulated by precisely placed hot air and become such a masterpiece. This art form inspired the current method of manipulating plastics to form many of the items we use every day, from water bottles to toys and so many things in between. This artful method is called Extrusion Blow Molding and it’s a common and inventive way of mass-producing hollow, lightweight products that are also durable and waterproof

How to select a Blow Moulding Machine?

The reputation of the blow moulding machine manufacturer you do business with has a lot to do with the quality of the equipment it sells. The right company takes great pride in offering its customers top-of-the-line products at a competitive price. Buying a blow moulding machine can be a nerve-racking experience for fresh entrepreneurs.

Types of products manufactured in Extrusion Blow Moulding Machine

Blow moulding is a manufacturing process for forming and joining together hollow plastic parts. In general, there are three main types of blow moulding: extrusion blow moulding, injection blow moulding (one stage), and injection stretch blow moulding (two stages). In the extrusion blow moulding process (EBM), plastic is melted and extruded into a hollow tube (a plastic parison). This plastic parison is then captured by closing it into a cooled metal mould. Air is then blown into the parison, inflating it into the shape of the hollow bottle, container, or part. After the plastic has cooled sufficiently, the mould is opened and the part is ejected. It is designed to manufacture high volume hollow plastic products.

Types of material used in Extrusion Blow Moulding Machine

When choosing a material for blow moulding; cost, density, flexibility, strength, and other factors should be considered into what resin is best for your part. If the elastomeric properties of the material are exceeded, a hole will tear through the material resulting in a defective part. Other relevant properties are largely based on your application and might include mechanical, physical, chemical resistance, heat, electrical, flammability or UV resistance.

Extrusion Blow Moulding Machine VS Injection Blow Moulding Machine

If you operate a business that requires specially formed plastic bottles or containers, such as juice and water bottles or liquid soaps and shampoos, it’s to your benefit to understand the various manufacturing processes for making those bottles and containers.

What are the 2 types of Extrusion Blow Moulding Machines?

Blow moulding is a manufacturing process used for the production of plastic bottles, containers, and custom shapes. At Central Machinery and Plastic Products, we use extrusion blow moulding (EBM). EBM bottles are easily identifiable by their pinch line across the base of the bottle. This line is created as the mould cavity closes on the parison and the tail is trimmed off.

The process of Extrusion Blow Moulding Machine

Extrusion Blow Molding is the simplest type of blow moulding. A hot tube of plastic material, called a parison, is dropped from an extruder and captured in a water-cooled mould. Once the moulds are closed, the air blown through the top of the neck of the container. When the hot plastic material is blown up and touches the walls of the mould, the material freezes, the container now maintains its rigid shape.

What is Extrusion Blow Moulding Machine?

Blow moulding is an umbrella term for forming hollow plastic parts by inflating a molten plastic tube or parison until it fills a mould and forms the desired shape. Think of it as inflating a balloon inside of a water bottle. The blow moulding process begins with melting down the plastic and forming it into a parison. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can pass. Water channels are carved into the mould to assist in cooling.