Blogs

Why CMP Machines are the BEST?

Innovation is at the heart of any successful company. Innovation keeps an organization at the top of their game, allowing them to flex their competitive muscles and take pride in the work they do.

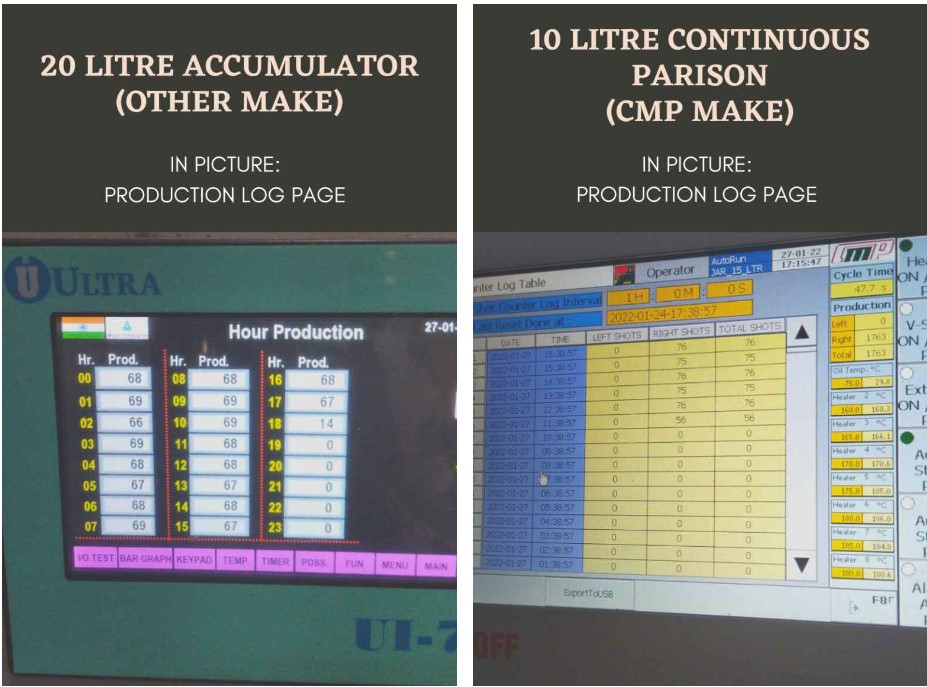

As always, we have proven why CMP is the best. How? Well, coming forward is a customer’s experience on how CMP’s machines give more production than other company’s machines. Also, they have kept both machines side by side to prove it.

Recent a customer bought CMP 10000/H/1 machine for his 15 ltr product. He is running a 15ltr product on CMP continuous parison machine. On other hand, the customer has a 20-litre accumulator machine (other make).

PRODUCT:

15 LTR EDIBLE OIL JERRY CAN

YELLOW JERRY CAN

The customer is running the same product on both machines. CMP 10 litre machines can give more production as compared to another 20-litre machine.

We have attached screenshots of both machines’ plc below:

Now working on the costing part the CMP 10 ltr machine is economic as compared to the other make 20-litre machines. The electric power consumption of the CMP 10-litre machine is less than the other make 20-litre accumulator machine.

Following are the technical details of the 10 ltr CMP machine:

| MODEL | UNITS | 10000/H/1 |

| EXTRUDER DETAILS | ||

| Screw diameter | MM | 75 |

| L.d. Ratio | L/D | 20:01 |

| Blowing capacity | ML | 10 LTR. |

| Screw speed | R.P.M | 0-75 |

| Accumulator Head Capacity | – | |

| Plasticizing cap. | KG/HR | 70/75 |

| Heating zone | NOS. | 8 |

| Maximum die dia. Hd | MM | 180 |

| MOULD DETAILS | ||

| Mould opening stroke | MM | 300 |

| Min. Mould thickness | MM | 300 |

| Mould length | MM | 450 |

| Mould width | MM | 400 |

| Dry cycles/min. | NOS. | 8 |

| Max. Cont. Dia. | MM | 250 |

| ELECTRICAL DETAILS | ||

| Extruder drive | HP | 25 |

| Hydraulic drive | HP | 10 |

| Blower | KW/HP | 2.5 |

| Heating load | KW/HP | 20.3/27.4 |

| Total power of m/c. | KW/HP | 48.15/65 |

| Main cable rating | MM2AMP | 50-120 |

| OPTIONAL ACCESSORIES | ||

| Parisonprogramme | OPT | |

| 3 Point Hyd. P/C | INC | |

| Extruder Up & Down | INC | |

| Tube Sealing | OPT | |

| Bottom Blowing & Stretching System | OPT | |

| OTHER DETAILS | ||

| Oil tank capacity | LTR. | 280 |

| M/c. Dimension l x w x h | FT | 8 X 6 X 8 |

| Control panel dimension | MTRS. | – |

| Machine & panel wt. | KGS. | – |

| Air requirement | C.F.M. | 20 |

So now, we leave it to you to decide which is more economical and which is more expensive.

This is the reason why CMP make machines are renowned.

As we work to provide more productivity and at less running expenses