Blogs

The Future of the Extrusion Blow Molding Machine

Everywhere you look, competition among different industries has exploded. Thanks to a thriving market, companies that once struggled now see incredible success. Just as businesses need ways to stay ahead of the competition, so do extrusion blow moulding machine manufacturers. Because of that, they continually push to come up with more innovative solutions.

In response to increasing customer demand for superior-quality machines, manufacturers within the extrusion blow molding industry have to come up with designs that provide better precision, faster production, and lower costs. As that happens, the entire landscape among blow molding manufacturers has begun to change.

Already there have been remarkable improvements to the existing lineup of machines, but when you consider what the next few years hold, things become even more exciting. The challenges that the standards within the world of manufacturing face today are like nothing ever seen before. Customers want bottles, containers, and other plastic products with unique shapes and intricate detailing – but without spending more money.

Since the extrusion process results in a broad range of finished products used by multiple industries, extrusion blow molding manufacturers can anticipate the need for better machines to continue. Also consider that several different types of plastic used for this process, including PVC, LDPE, and HDPE, are in great demand; many manufacturers will focus changes on those specific materials.

With companies around the world increasing the production of quality plastic components like the food industry, Automobile industry, pharma industry, toy industry, and more, and with no letup in sight, manufacturing companies of extrusion moulding machines must come up with innovative solutions to accommodate the market demands.

Global Blow Moulding Machines Market: Regional Outlook

Manufacturers are shifting from mature regions to emerging countries, such as India and China. The global blow moulding machine market is anticipated to be dominated by the Asia Pacific region, with China leading the market, both in terms of production and consumption. India is also anticipated to witness sound growth in demand for blow moulding machines owing to the rapid growth being seen in the consumer packaging and automotive industry.

North America and Europe are collectively anticipated to hold a significant share in the blow moulding machines market and the growth in the automotive and electronics & electrical industry in the region is anticipated to drive the demand for blow moulding machines in the coming years. Significant investments and recovering economies of Brazil and Argentina are projected to drive the Latin America blow moulding machines market. The Middle East and Africa are projected to witness moderate growth in demand for blow moulding machines over the forecast period due to the initiatives being taken by various Middle-East countries towards achieving a diversified economy.

Technology Insights

The extrusion blow molding technology segment led the market and accounted for a 37.0% share of the global revenue in 2020. The extrusion process is comparatively cheaper than other processes and hence majorly utilized in bulk manufacturing of packaging products, bottles, and cans.

The cost of extrusion blow mould is lower than the injection blow mould due to the lower pressure requirement in the former. The machinery costs are also lower for the extrusion process, which is an added advantage. Moreover, moulding of external threads is easy and cheap with this process. Hence, it is also expected to be the fastest-growing technology segment over the forecast period.

Injection blow moulding offers the advantage to manufacturers of more complex products in several designs and shapes that otherwise would be impossible or difficult with other technologies and the cost of the end products would be considerably higher as well. This process enables companies to increase their production output in a relatively shorter time along with flexibility, in terms of design and materials that can be used. However, heavy machinery design, which occupies greater space, and high costs associated with it may hinder the segment growth.

Central machinery and plastic products have always played a significant role in providing the latest technologies in the blow moulding sector. They have a dedicated R&D team which constantly working to provide solutions and innovate new technologies. Because of this, they hold a major position as alpha leaders in the blow moulding sector.

Product Insights

The Polyethylene (PE) product segment led the market and accounted for more than 20.0% share of the global revenue in 2020. This significant share is attributed to the increased use of PE compounds in the packaging and electrical & electronics industries. Major applications of PE compounds include different grades of bottles used for packaging a wide range of products, such as food and chemical products.

Apart from the packaging industry, construction is one of the leading applications for PE compounds. Polyethene is used for prototype development on Computer Numerical Control (CNC) machines and 3D printers. High-density Polyethylene (HDPE) offers easy processing at low cost, a good moisture barrier, and holds the ability to produce opaque and hollow packaging products. Low-density Polyethylene (LDPE) is often preferred, based on the field of application, due to low cost of production, heat-seal ability, high clarity, high elongation, and softness.

The demand for Polyethylene Terephthalate (PET) in packaging is expected to gain traction over the forecast period. Recent developments in PET bottle disposal and recycling have offset the limitations caused by regulations. Moreover, the development of bio-based PET is expected to provide the much-needed scope for internal substitution, thereby driving its demand in various applications. It is widely used in the plastic bottling of soft drinks and for speciality bottling, such as bottling of beer. It is an ideal material for flexible food packaging and thermal insulation owing to some of its properties. It is also often used as a substrate in thin-film solar cells.

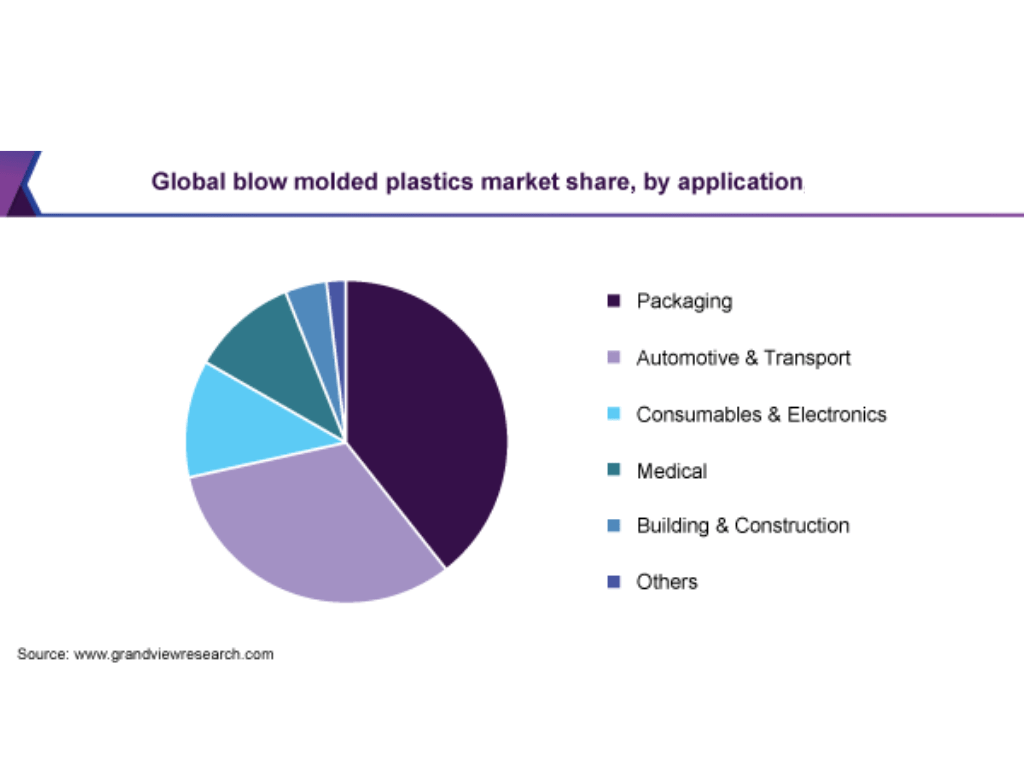

Application Insights

The packaging application segment led the market and accounted for more than 39% share of the global revenue in 2020 owing to increased use of packaging products as a result of high consumerism in emerging economies. The packaging industry is driven by the rising demand for personal protective kits, face masks, face shields, and others along with high consumerism in emerging economies. The growth of the packaging industry is projected to boost the demand for plastic compounds, such as PE and PET in the future.

Various regulatory bodies have stipulated guidelines regarding packaging materials in food contact applications. Bisphenol A (BPA), which is often employed to produce plastics and epoxy resins, has been under great regulatory scrutiny, particularly due to its presence in plastics used in packaging’s, such as PVC and polycarbonate. Polypropylene (PP) is primarily used in the flexible packaging of certain food & confectionery items, clothing, tobacco, and others.

Apart from flexible packaging, it has vivid use in the rigid packaging of PP bottles for mineral water and edible oil. It is also used in automotive, consumer products, such as housewares, furniture, appliances, luggage, and other applications. Many automobile manufacturers prefer plastic vehicle parts, which help achieve low-cost production and increase the bottom-line profit margin of the companies.

Sales of these goods are highly dependent on the buying habits of the consumer and hence directly affect the overall market dynamics. Growing population, economic development, and improved purchasing power in the emerging markets are likely to boost the sales of consumer goods, thereby propelling market growth.

Keeping Up with Demand

Central machinery and plastic products closely watch global changes and listen to what customers want to ensure. Central machinery and plastic products offer the best machines available for the extrusion moulding process. For excellent service and affordable prices, contact us today.