Blogs

SWELLING BEHAVIOUR OF THE PARISON

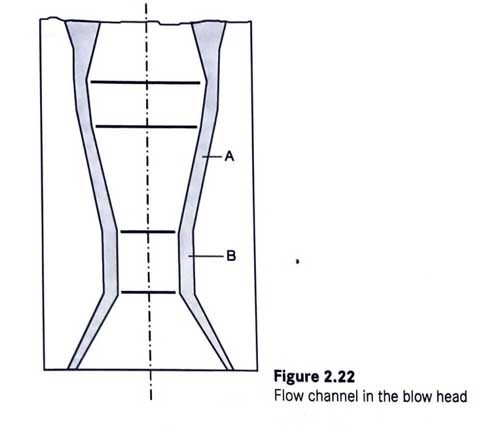

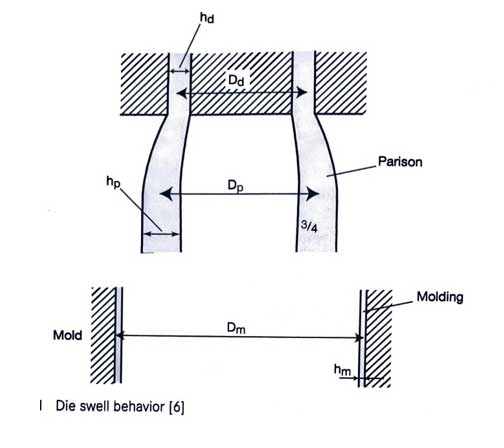

The visco – elastic behavior of the thermoplastics (here the memory effects) in conjunction with the flow channel geometry in the head causes the diameter of the parison to change after leaving the die. The wall thickness also changes and thus the length of the parison. This phenomenon is called ‘; die swell’’. Continuous extrusion and accumulator head production lead to different swelling behavior.

In the area where the melt enters the die area. The diameter is significantly reduced in most heads so that the melt is stretched and accelerated in the direction of flow. This leads to high molecular orientation in the melt. If the melt were they emerge from the head into the open air at the end of such a deformation here, the swell effects would be particularly strong due to the memory effect.

The extent of the swelling is reduced the longer this zone is . Any change in the flow channel affects orientations in the molecular structure. The swelling behavior of a parison is therefore highly dependent on the exact geometry of the die in the blow head, in addition to the raw material properties, the output speeds, and the temperature conditions (swelling is less pronounced at higher temperature.

This swell effects must be considered accordingly when designing the die diameter. The exact swell factors for die design must be determined individually for the respective raw material and processing conditions. For this purpose, e.g. special molds are used which do not have any inflation cavity but only flatten and cool the ejected parison. The swelling factor can be determined on the plates thus produced