Blogs

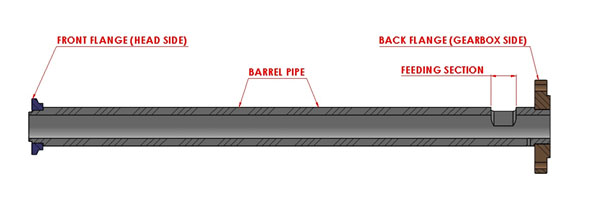

SMOOTH BORE EXTRUDER

Blow molding machines with smooth – bore extruders are more or less limited to the processing of low to medium molecular weight polyolefin types. Smooth bore extruders are less expensive than those with a grooved feed zone and show less screw wear. The energy operating costs are lower because no intensive cooling or temperature wear. The energy operating costs are lower because no intensive cooling or temperature control of the grooved (feed zone) is required. Smooth – bore extruders (length 25 D, on blow molding machines less frequently up to 30 D) are certainly suitable for universal processing of PE and PP up the range of raw materials with a medium molecular weight, i.e. low to medium melt viscosity.

However, if high molecular weight grades of PE and with higher viscosity are to be processed, the conveying efficiency of smooth – bore extruders usually drops. This leads to excessive melt temperatures reduced throughput rates. The high temperatures impair the production quality and often make the production of certain parts impossible, as the strength of melt is significantly reduced. This results is an uncontrollable sagging of the parison.

Smooth – bore extruders are therefore particularly suitable for the large scale production of small hollow parts of low and medium molecular weight grades of PP and PE under constant extrusion conditions. Regarding the drive, PP requires approximately the same amount of energy as PE, i.e. a maximum of 0.23 to 0.25 kWh/kg in continuous operation. During start up and when increasing the screw speed, however, peaks can occur for short periods, which are about 25 to 32% higher. These values refer to the effective electrical power absorbed by the drive motor; gearbox and thrust bearing losses are thus included. If the values are high than indicated, the screw is not optimal and conducts too much shear energy into the melt, which is thus overheated.

For screw lengths from 25 to 30 D, the use of decompression screws with usually two mixing sections is recommended for PP and PE. Shear elements should be avoided. The mixing parts consist of rings with eight gaps around the circumference , each approximately 8.6 mm wide, which integrated into the discharge zone.