Blogs

Rotational Molding: Advantages and Disadvantages

What is Rotational Blow Moulding?

Rotational moulding offers a number of benefits, but it’s not the best production process for every part. So how do you decide if it’s a fit for you? Understanding the advantages and disadvantages of the process is the first step toward making a decision with confidence.

Rotational Molding Uses

Rotational moulding, also known as roto-moulding, is a thermoplastic moulding process best suited for large, one-piece hollow parts and double-walled open containers such as tanks, kayaks, and coolers. It’s most cost-effective for production volumes of less than 3,000 annually, making it ideal for inventors, start-ups, and small businesses.

Rotomolding is often used for parts that require high-quality finishes, uniform wall thicknesses, and high stability. Features such as inserts and spin weld attachments can be incorporated directly into the roto mould and foaming can be used to create thermal insulation and stiffness. Unlike competitive processes such as blow moulding and thermoforming, roto moulding produces no pinch-off seams or weld lines, resulting in a finished product without the use of secondary processes.

Rotational Molding Process

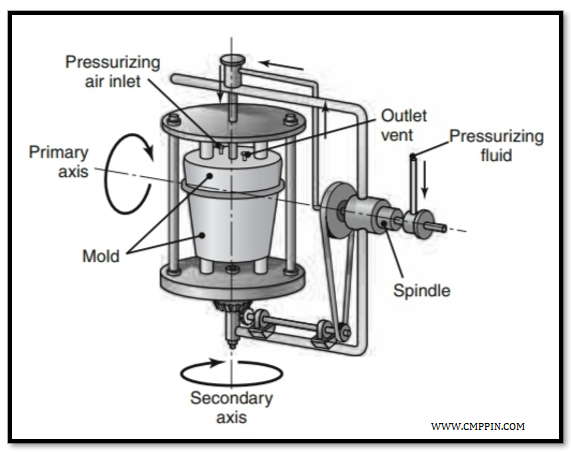

The rotational moulding process is quite simple:

- A hollow mould is filled with powdered plastic resin.

- The mould begins rotating bi-axially and is transferred into an oven.

- The mould continues to rotate as the resin melts and coats the walls of the mould.

- The mould is cooled until the resin hardens into the desired shape.

- The rotation is stopped, and the mould is opened to remove the finished part.

Given the low-pressure, high-heat nature of the process, rotomolded tooling is usually made from soft metal such as aluminium and the majority of the resin used is polyethene due to its low chemical degradation when exposed to high heat. Inserts, ribs, kiss-offs, undercuts, and foam reinforcements are often incorporated into the part in mould or by means of secondary processing.

Advantages and Disadvantages of Rotational Molding

The main difference between the rotational moulding and competitive moulding methods such as blow moulding and thermoforming is that the resin melts into the mould walls instead of being forced by pressure. This distinction gives way to a number of advantages over other manufacturing processes but also carries its share of drawbacks.

Advantages of Rotational Molding

Rotomolding boasts a number of advantages over comparable moulding methods:

- Low-cost tooling: low operating pressures allow rotomolded tooling to be crafted from low-cost metals such as aluminium

- Consistent wall thickness: the constant rotation of the mould coats the walls evenly during both the heating and cooling processes

- Double-wall construction: complex double-walled open containers can be produced without secondary processing

- High durability: parts are moulded as one solid piece, eliminating the need for joining techniques such as welding and joint fabrication which creates weak spots

- High stability: the moulding material isn’t exposed to external pressure, increasing its stability and reducing the risk of defects in the finished part

- High strength: roto-moulding creates thicker corners, reducing the risk of failure in these stress-concentration points

- Appearance: the soft metal used for the roto mould tooling easily accommodates surface finishes such as fine-detail textures, logos, symbols, and lettering

Disadvantages of Rotational Molding

As with any plastic moulding process, roto moulding has its disadvantages:

- High cycle times: at eight rotations per minute, roto moulding can take up to three hours to complete one part

- Limited material options: raw material used in roto moulding must be readily converted from granules to a fine powder and must have high thermal stability, limiting material selection to poly-based resins

- High cost of raw material: material costs are high due to high thermal stability requirements, the cost of required additives, and the cost of grinding the material into a powder

- Low repeatability: the soft metal used in roto mould tooling must be refurbished or replaced after 3,000 cycles, inducing quality issues due to a lack of repeatability

- High labor costs: mechanization and automation have not yet been realized for roto-moulding, requiring greater labour intensity than comparable manufacturing processes

Summary:

- Rotational moulding is a plastic casting technique that produces a hollow, seamless, and double-walled part by heating a powdered resin in a hollow mould tool while being slowly rotated and cooled to solidify. This process started hundreds of years ago, was popularized in the mid-20th century, and is still developing. This process has a variety of applications.

- The rotational molding equipment consists of a mold, ovens, and a cooling chamber. The type of rotary moulding machine is distinguished by the direction in which the mould travels according to the sequence of the process.

- The types of rotational moulding equipment are clamshell machines, turret machines, shuttle machines, vertical wheel machines, rock and roll machines, and open-flame machines.

- Loading is the first step wherein the fine, homogenized, and dried powdered resin is placed in a mould coated with a mold release agent. The resin is heated while being slowly rotated in a bi-axial direction until it is molten and covers the entire tool. The moulded part and the entire mould are gradually cooled by convection to room temperature, wherein they can be safely removed.

- Critical parameters of the rotational moulding process are heating time, cooling rate, and rotation ratio. These settings determine the mechanical properties and dimensional quality of the parts to be produced.

- The polymer resin must have high thermal stability, flow easily in its molten state, and have antioxidant groups in the molecular structure. The resin must be easily ground to powdered form. Polyethene is the most commonly used polymer.

- The advantages of rotational moulding are the creation of parts with uniform wall thickness, inexpensive tooling, the flexibility of production, less downstream process, and less wastage of the resin. Large and double-walled parts are also easily created.

- The disadvantages of rotational moulding are a high cycle time attributed to long heating and cooling cycles, limited material options, short tool life, and difficulty of moulding some details.