Blogs

Mold Support & Venting

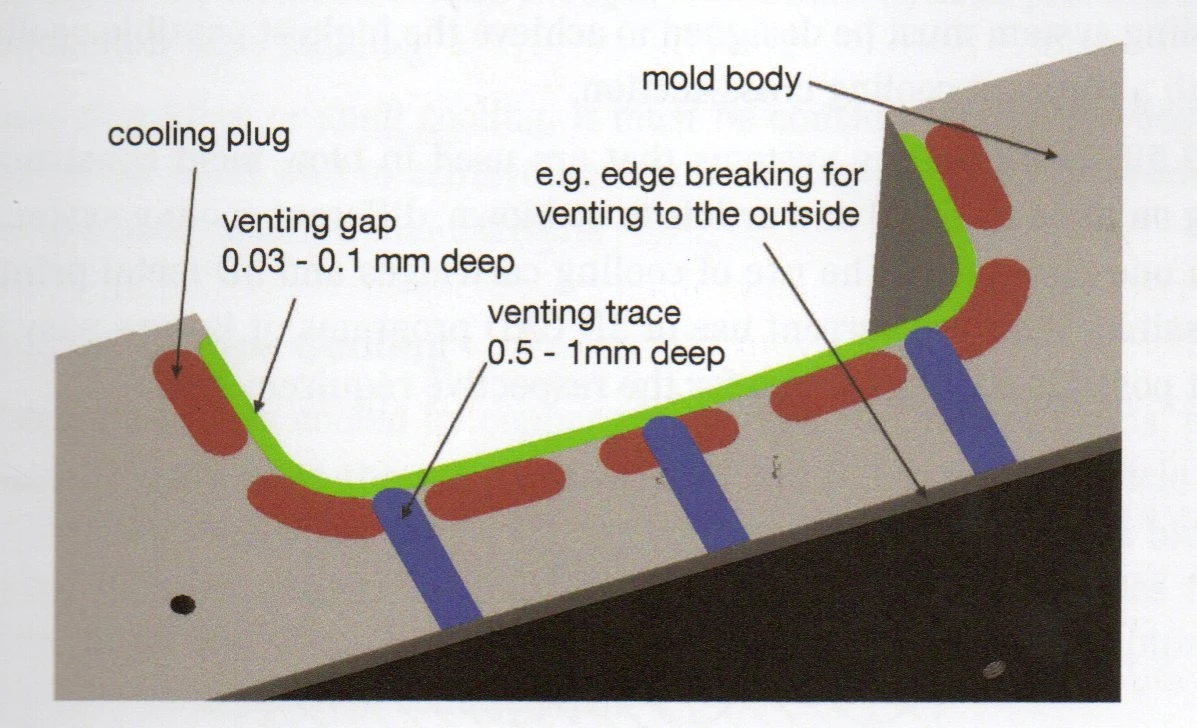

Figure 2.56 Venting traces between the individual mold parts (Illustration : Werkzeugbau Leiss)

Mold support

On the outside, blow molds are provided with support surfaces to prevent damage to the cutting edges, especially in set-up mode, i.e. when closing the mold without plastic. The mold support also serves to transfer excess clamping force. This increases the service life of the blow molds and forces a parallel mold closure. Mold supports must also be fitted for blow molds that are significantly shorter than the machine clamping platens. This distributes the clamping force evenly over the clamping platens. The thickness of the mostly round supports is adjustable on one side to regulate the cutting edge pressure, if necessary.

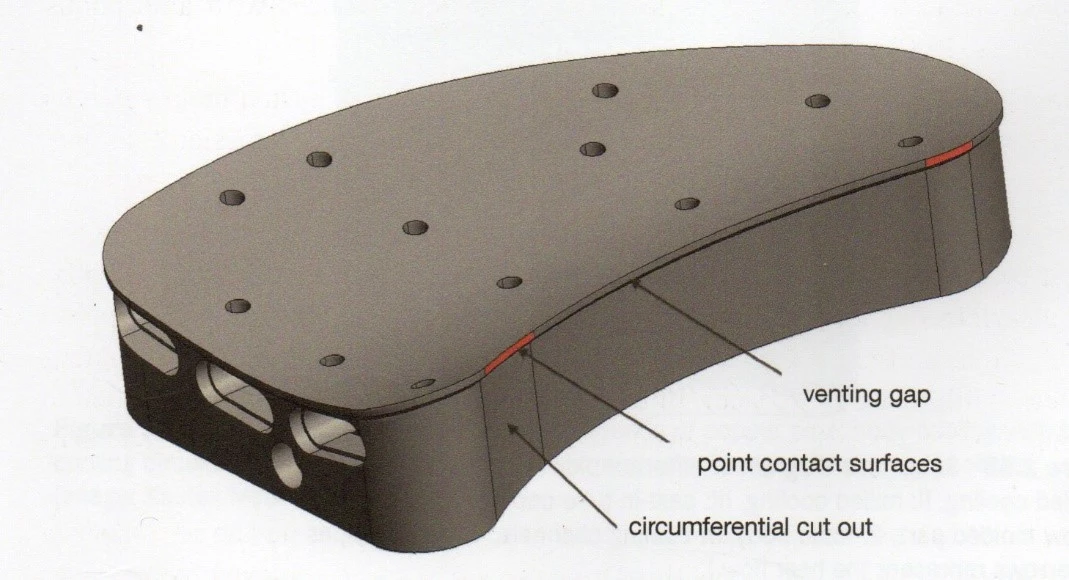

Figure 2.57 Engraving insert with integrated venting in the circumferential area of the insert (Image: Werkzeugbau Leiss GmbH)

Mold venting

For a perfect article surface. Blow molds must be optimally vented. In general, blow molds are vented in the area of the mold parting line; this applies both to the longitudinal parting line between the mold halves and to transverse parting lines between the mold parts of the individual mold halves. Usually venting slots with a depth between 0.03 mm and 0.1 mm are used. Fine venting for blow mold surfaces for processing polyolefins is done by cross-polishing followed by sandblasting, this also improves the cooling of the mold. The roughness depends on the plastic, the article volume. And the article design.

With amorphous, non-colored plastics, like PVC, PETG, or PET, the surfaces must be polished to achieve the desired transparency and brilliance of the blow molded parts. Sandblasted mold surfaces least to matt article surfaces with amorphous plastics (e.g. PVC ).

Depending on the article, micro-sand-blasted or glass bead blasted mold surfaces are preferred, as these provide a more homogeneous surface impression than polished surfaces.

Blow molds for “in-line fluorination’’ must be particularly well vented. Due to the partial pressure gradient and the resulting diffusion behavior of the F2/N2 mixture, a certain F2 concentration in the mold area cannot be avoided. This leads to deposits in or on the blow mold. Furthermore, welding seam problem or welding problems with inserts can occur. In molds for F2 operation, a vacuum is applied to the mold vent. Slotted dies or grooved pins [29] are suitable as venting aids in critical areas.

Depending on the size, depth, and position of the engraving, it may be necessary to vent the engraving. A venting within the engraving can be achieved using micro venting holes (diameter up to 0.03 mm). With such small drillings, it is also possible to vent the thread in the threaded area of bottlenecks without getting a disturbing marking on the article.

In addition, vent slot dies can be used at critical points in the blow mold to achieve better blowing and thus a better surface on the blow molded part. Such venting dies must always be uses in the blow, for example, if the handles of jerry cans are squeezed off.

In the circumferential area of engraving inserts in blow molds, the contour can also be provided with a vent.