Blogs

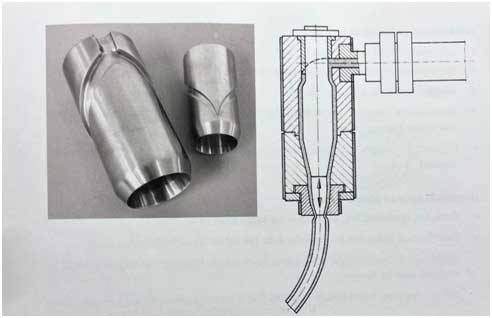

MANDREL HEADS IN EBM

In mandrel heads (also referred to as ‘’heart – shaped – curve heads’’, or cardiodid heads) the solid core part is massively integrated into the basic structure of the head. These heads are also called side-fed heads. The solid melt strand is diverted intotwo halves,both going halfway around the torpedo to meet at the opposite side. A certain amount of melt flows down through a narrow gap at the same time. Basically, a mandrel head can be compared with a coat hanger die used in sheet extrusion; however, it is bent into a ring.

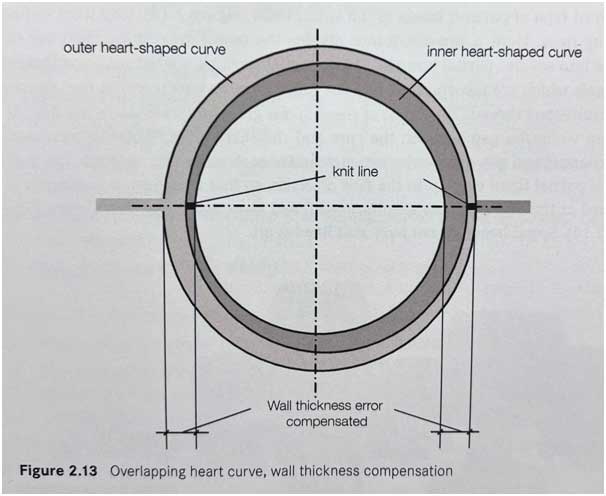

Mandrel heads only have one knit line. Even if this continuous knit line is not necessarily visible in the finished part, its acts as a weak point and can lead to failure of the article under load (internal pressure, upsetting pressure). To minimize the weakening effect of this knit line, two overlapping heart-shaped curves are often used. This way, two knit lines, both going only halfway through the wall thickness, are arranged opposite each other. Mandrel heads show a material dependent behavior. This means that different material with different flow behavior show different circumferential wall thickness distributions. The 180® offset and over lapping heart shaped curves compensate for this effect, and the parison shows an equal wall thickness distribution over its circumference.

Advantages of Mandrel Heads

- Low manufacturing costs

- High precision of the annular gap width

- Multilayer heads are possible

- Inexpensive construction of the axial wall thickness control by means of a pull rod inside the mandrel.

- Support air supply with longitudinal bore in the mandrel can be easily implemented

Disadvantages of Mandrel Heads

- Complex optimization, especially for large head diameter

- Distribution behavior is dependent on the material and operating point

- Optical and mechanical weak point in the knit line area of single mandrels without special design

For overlapping heart shaped curves, the color changeover times are quite long