Blogs

HOW TO SELECT TOOLING IN BLOW MOULDING MACHINE :

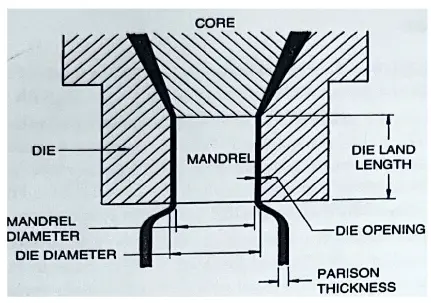

With a basic understanding of the differences in the types of head tooling

available, we can now look at calculations that will help make our tooling

choices. It is important to keep these points in mind:

Parison diameter is dependent on head tool size, resin characteristics,

regrind content, temperature, and punch-out speed.

Head tooling diameter is determined by part shape and size.

Head tooling diameter determines the size of machine required.

With emphases on the second point, use the following formula to match the

head tooling part.

Tool diameter =

where

W = width of part,

T = thickness of part.

For a simple panel that is 6 units wide by 2 units thick, inserting these

numbers into the tool formula will give us an approximate tool size

required.

Example:

This calculation suggests that a 12.7 cm (5 in.) tool will be a starting point.

The effect of blowup rate and extrusion rate on the total tool size is show

below. Blowup rate can be inserted into the formula D/B.

= Best tool for the job = = C

where

D = tool diameter,

B = blowup rate,

C = 2.54 = proper tool for job.

Unfortunately not all parts are so simply designed as in this example. In

cases where parts are more complex it is important to obtain an accurate

measurement of the part periphery. Once that answer is found the original

formula can be used. Use the following exercise to practice:

Panel to be molded