Blogs

Extrusion Blow Moulding Machine VS Injection Blow Moulding Machine

If you operate a business that requires specially formed plastic bottles or containers, such as juice and water bottles or liquid soaps and shampoos, it’s to your benefit to understand the various manufacturing processes for making those bottles and containers.

Having an understanding of the different manufacturing processes and knowing what method is best suited to product production, is important for all aspects of prototyping, planning, manufacturing, and costing.

There are various methods followed such as EBM, IBM, IM etc. Today we are talking about EBM VS IBM.

Both injection blow moulding and extrusion blow moulding processes are essential for many manufacturing purposes. These techniques are used to create many disposable and recyclable plastic parts, including products used in medical and research applications. Both processes feature unique functions to produce different results, which is why it’s important to understand each process to determine which is suitable for manufacturing a particular product. To help you better understand the differences between injection blow moulding and extrusion blow moulding, we’ll go over how each process works so that you can determine which is best for your needs.

BLOW MOULDING MACHINE

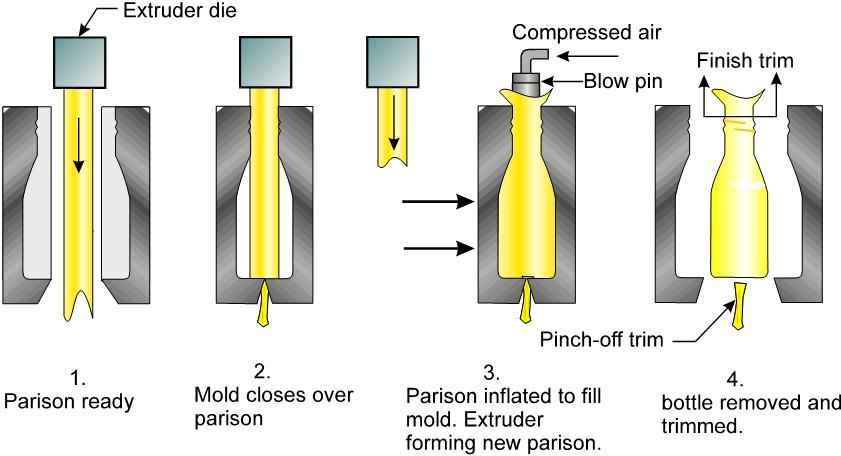

Extrusion blow moulding (EBM) is a manufacturing process whereby plastic is melted and extruded into a hollow tube called a mould. The parison is held and sealed in the metal mould. Air is then blown into the mould, thereby shaping it into the desired shape of the bottle or container. Once the plastic has cooled, the mould is opened and the part is discharged.

IBM shares many technological characteristics with conventional injection moulding. Many of the techniques for reducing energy use in injection moulding can be simply and directly transferred to IBM. These include improved setting, barrel insulation, improved motors and drives, all-electric machines, improved control of ancillaries and improvements in tool design. The additional blowing step needs control but does not add much to the direct energy use of the machine, although it adds it through the increased use of services such as compressed air for blowing.

IBM is primarily a process used for packaging and articles with less weight & high accuracy.

The main difference between blow moulding and injection blow moulding is that blow moulding is used for making hollow parts like water bottles and liquid soap containers. One of the key benefits of blow moulding is that it can be used to manufacture complex shapes – something that can be of tremendous value for such things as product branding and identity.

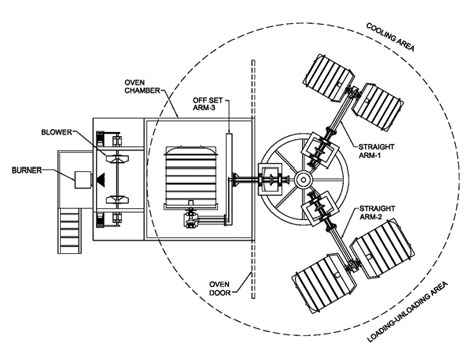

The injection blow moulding (IBM) process uses an injection moulding machine rather than an extruder to produce the precursor. This precursor is called a preform rather than a parison as in extrusion blow blowing (EBM). A major advantage in IBM vs. EBM is that the preform shape can be designed to receive a more consistent or desired wall thickness when Blow Moulding. The process consists of blowing a molten thermoplastic against the inside walls of a female mould cavity and chilling it to a rigid solid product. The IBM machine has an integral injection unit and a multi-impression mould assembly in which the mould cores are usually mounted on a rotary table.

These techniques are used to create many disposable and recyclable plastic parts, including products used in medical and research applications. Both processes emphasise unique functions to produce different results, which is why it’s important to understand each process to determine which is suitable for manufacturing a particular product.

INJECTION BLOW MOULDING MACHINE

The Key Differences Between Injection and Extrusion Blow Molding

There are three main areas in which injection blow moulding and extrusion blow moulding differ.

Types of Materials

Extrusion blow moulding is most commonly used to form products out of:

- High-density polyethylene (HDPE)

- Polypropylene (PP)

- Polyethylene terephthalate (PET).

Injection blow moulding is most commonly used to form products out of:

- Acrylic

- Polycarbonate

- Polyoxymethylene (POM)

- Polyethylene (PE)

Products

The principal difference between IBM and EBM is the type of products they create. IBM is typically used to form more solid parts which are less in weight & need accuracy. Meanwhile, EBM is used for manufacturing more hollow parts like bottles and other containers. Extrusion Blow Molding can manufacture more complex shapes due to how the product is formed. However, injection blow moulding can produce large volumes of quality parts quickly and accurately.

Moulds

For IBM, there needs to be a high precision match between both halves of the mould to enable total control over the flow of resin. Most of the work involved in injection blow moulding involves producing the mould. In EBM, there is a higher level of design flexibility between both mould halves since each half forms its wall shape.

EBM Advantages

- Low initial mould tooling costs.

- The flexibility of tooling; moulds can accommodate interchangeable neck finishes.

- Container sizes can range from less than 1 oz. to 55 gallons.

- Container shape is not restricted; bottles can be long and flat or have handles.

- Wide selection of machinery; tooling can be specifically geared to package volume requirements.

EBM Disadvantages

- Containers have a flash that must be trimmed and reclaimed.

- Unit cost is significantly higher than injection blown bottles in less than 5 oz. capacity.

- Operator skill is critical to control container weight and quality.

IBM Advantages

- Scrap free process; bottles require no trimming operation.

- Neck finishes are injection moulded (not blown) at a high level of accuracy.

- Weight control is extremely precise and material distribution is uniform.

- Unit cost is extremely low for small capacity containers (5 oz. or less).

IBM Disadvantages

- High tooling cost.

- No mould flexibility.

- Not economical over 16 oz. capacity.

- Container shapes are limited to a blow-up ratio of 3:1 or less (diameter of container to diameter of neck finish).

- Not well suited for handle ware.

While the final shape required for a part often dictates the process used, both extrusion and injection moulding have their advantages.

The choice between IBM and EBM, true of all packaging-related choices, should reflect application specifics. Acknowledging the difference in words, the following are some generalizations about specifics:

- The type of container can be determined; for example, containers that have handles are better suited for EBM, while wide-mouth containers are better suited for IBM;

- If the tightest tolerances (especially in the neck finish and in wall thickness) are required, the nod should go to IBM;

- Regarding coextrusions, the more complex the structure, the more it favours EBM;

- EBM generates scrap (in the forms of flash and trim), although they’re fed back into the process, IBM generates no such scrap;

- When factoring in mould costs, it should be borne in mind that IBM requires two types of moulds but EBM only one; and,

- With the issue of overall costs casting its shadow, the greater the annual quantities the more conditions point to IBM.

Overall, we know the simple difference between EBM and IBM is that; in the type of product which is produced by the respective processes. The extrusion blow Moulding process creates a two-dimensional product whereas the injection blow Moulding process creates a three-dimensional product as the final output.