Blogs

CLAMPING UNITS IN EXTRUSION BLOW MOULDING

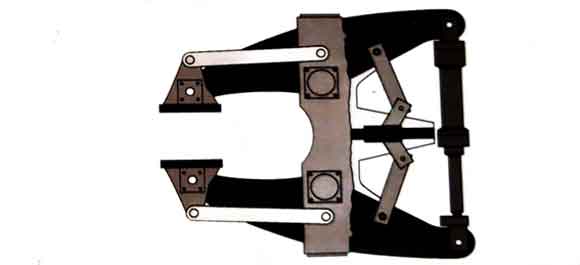

Two-platen toggle clamping unit

In all extrusion blow molding processes, a blow mold consisting of two halves closes around the parison once it has reached its full length. These two halves of the mold are mounted on the so-called mold mounting platens, which from part of the clamping unit (or closing unit). Clamping units have the following main tasks:

- Mounting of the blow molding tool.

- Movement under the parison head (in some cases, see above).

- Closing the mold around the ejected parison.

- Building up of the closing force (clamping force), which is required to

- Squeeze off the parison in the cutting-edge area, so that the article can be easily removed, automatically or manually.

- Hold the mold against the inflation pressure (8 to 10 bar).

- Supplying the blow mold with cooling water.

- Supplying the blow mold with compressed air or hydraulic oil for moving molded parts (core pulls).

The closing force is applied either hydraulically or electrically. A combination of both systems is used in hybrid solutions.

These hydraulic clamping units are mounted horizontally and open/close like tongs. They are mostly used in continuous extrusion and move horizontally between the so-called head position and the blowing position.

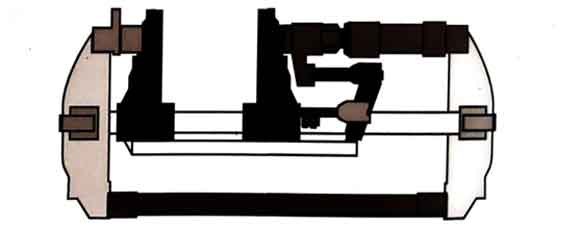

Small “three-platen” clamping unit

This hydraulic clamping unit has only one hydraulic cylinder, which moves both platens symmetrically to the mold parting line, synchronized by a (toothed) belt or lever system. These clamping units stand upright and are also used in double-station machines, where the two clamping units alternately take over the parisons one after the other.

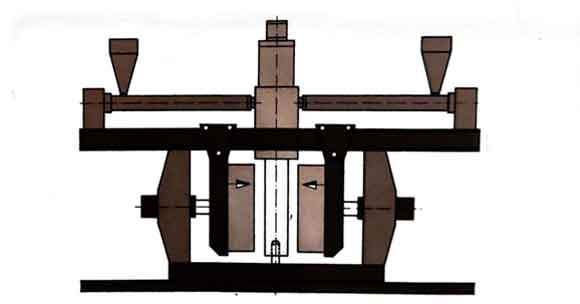

Large clamping unit with two hydraulic cylinders

For larger blow molded parts, large clamping units are used, often as stationary units in combination with the accumulator head process or with parison transfer units. The platens in these clamping units with two hydraulic clamping cylinders can be arranged suspended from the extruder platform or standing on the machine frame. The clamping platens in the “three-platen” systems are synchronized via a toothed belt.