Blogs

Can Extrusion Blow Molding Produce Complicated Shapes

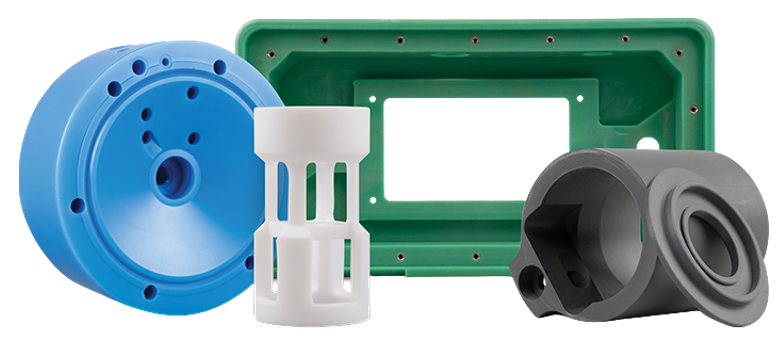

When it comes to extrusion blow molding capability, most people think of standard plastic bottles, tight-head containers, jars, and larger water containers. However, the extrusion blow molding process can do much more. In fact, when using a technologically advanced extrusion blow molding machine, it can produce finished products with complicated shapes, and in varying sizes.

Understanding the Extrusion Blow Molding Process

Especially for achieving complicated shapes, it is imperative that you rely on a superior quality machine for extrusion blow molding. The reason is that unless the melted resin flows into the mold evenly or if some other mishap occurs, you could expect to see a warped and unusable product. Fortunately, the right machine ensures a seamless extrusion blow molding process that yields outstanding finished products.

While you expect this machinery to produce water and soda bottles, jars for various food products, containers for car oil, and so on, it can also create all types of more challenging shapes. As a perfect example, in place of metal gas tanks, most automakers now rely on plastic. Although a large but also uniquely shaped item, the extrusion blow molding process is ideal. This process is also perfect for making plastic car seats, mannequins, and a broad range of other products with complicated shapes.

Turn to the Best

For both conventional and complex plastic shapes, you need to work with a state-of-the-art extrusion blow molding machine. With that, you have the assurance of achieving a stellar finished product. At PET All Manufacturing, a leader in making excellent machinery, we have a solution for your specific needs. Every machine we sell boasts special features like high-impact resistance, controlled wall thickness, lightweight yet durable, flexible part design, and environmental resistance.

Why settle for second best when you can turn to us for the best.

One of our representatives will patiently answer your questions and provide information to help you make an all-important decision.

yes it can make pretty complex shapes so long as they are hollow.

One of my favourite examples are the fuel tanks used in cars these days.

Imagine the rigor with which they are tested for impact strength, puncture resistance, impermeability (in part due to complex multi material extrusion which will include a nylon barrier layer) and of the blow moulded seals and welds.

The complexity of the system they are being used for, carrying and dispensing fuel while moving and vibrating this requires complex parts fitted into and in addition to the blow moulded container.

But the real magic is that you no longer need to make space for a metal box of fuel, you can instead make the fuel tank fit into the negative spaces between things in the car. In other words that tank can now be of any shape.

Blow molding is used for hollowed parts, but not say complicated or not. It depends on the design:

- The most common used processing is plastic injection molding. And usually it can do with very complicated parts.

- The blow molding processing is used for hollow shapes. Usually, blow moulds are made of Aluminium, and cheaper than injection moulds.

- If the part is design for blow molding processing, there are also some rules should be followed: the part should be hollow shape with only one hole, the hole is smaller than the widest area of the part. The parting line should be accepted. For bottles, the bottom should be debossed upwards that the bottles can “stand” on the table.