Blogs

EXTRUDER WITH GROOVED FEED ZONE

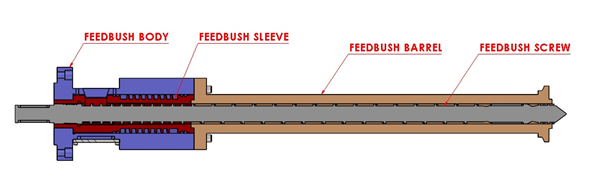

Blow moulding machines with grooved barrel extruders are universal machines for all types of polyolefin; the grooved barrel system is,however, indispensable for high molecular weight, high viscosity raw materials. In these extruders, the cylinder wall in the feed section features tapered longitudinal grooves. The feed zone must be intensively cooles when processing polyolefin. The material is taken by the screw and as a result of the pallets being wedge in the grooves, is compressed to form a kind of spindle nut which is prevented from rotating in the grooves and is pushed forward by the rotating screw. This leads to forced conveying. The cooling and heat separation of the extruder prevents the raw material from melting already in the area of the grooves, clogging the grooves, and thus causing the forced conveying to collapse.

In polyolefin processing, the system are almost always equipped with shearing and mixing parts; the shearing parts are also necessary for highly viscous melts due to the high conveying efficiency. Such systems can be optimized much more easily and over a wider range than the barrier screws that are also used. This applies all the more if the shear and mixing elements are designed to be interchangeable.

With highly effective systems, pure granulate (due to geometry and bulk density) usually shows a higher conveying efficiency than regenerated material (regrind). Therefore, the output of technical parts with a usually high regrind content can be much lower than for simple moulded parts, where the regrind content is only about 30%. With low regrind content, i.e. higher conveying efficiency, the melt must still be homogeneous. On the drive side, extruder with grooved feed zones are more complex than smooth bore machines: due to the high conveying efficiency, a 60 to 100% higher torque is required – if no higher drive power is required – which makes the gears more expensive. During start – up, torque peaks of more than 100% can occur compared to smooth bore extrudes.