Blog

CLAMPING UNITS IN EXTRUSION BLOW MOULDING

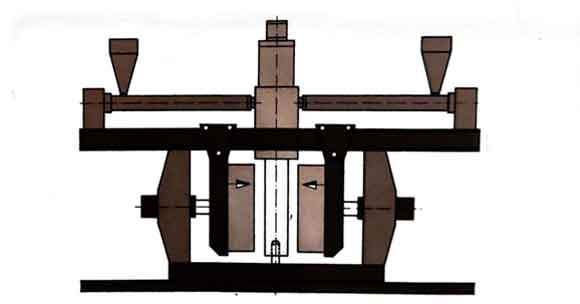

In all extrusion blow molding processes, a blow mold consisting of two halves closes around the parison once it has reached its full length. These two halves of the mold are mounted on the so-called mold mounting platens, which from part of the clamping unit (or closing unit).

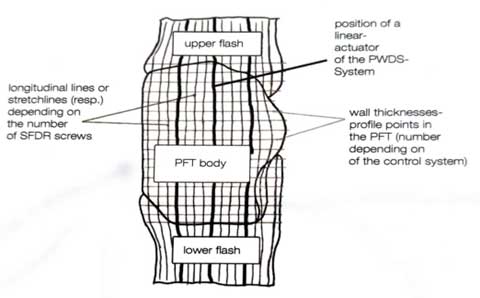

RADIAL WALL THICKNESS DISTRIBUTION IN BLOW MOULDING

In blow moulding, the wall thickness distribution of the finished article is essentially determined by the wall thickness distribution of the parison, its position in relation to the blow mould cavities, and the local stretching paths.

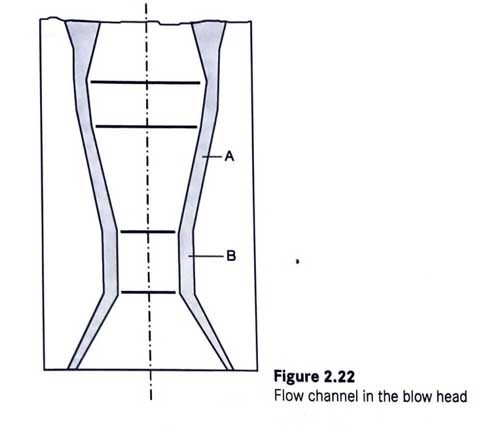

SWELLING BEHAVIOUR OF THE PARISON

The visco – elastic behavior of the thermoplastics (here the memory effects) in conjunction with the flow channel geometry in the head causes the diameter of the parison to change after leaving the die. The wall thickness also changes and thus the length of the parison. This phenomenon is called ‘; die swell’’.

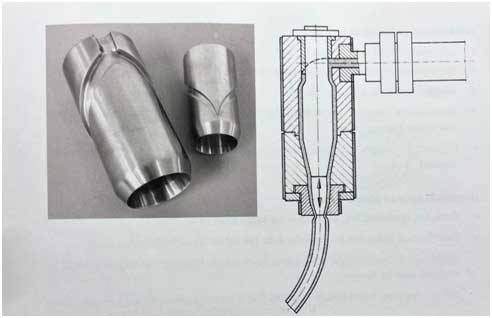

MANDREL HEADS IN EBM

In mandrel heads (also referred to as ‘’heart – shaped – curve heads’’, or cardio did heads) the solid core part is massively integrated into the basic structure of the head. These heads are also called side-fed heads.

SPIDER HEADS IN EBM

The main task of parison heads (blow heads or even just heads) is to divert the compact melt flow as supplied by the extruder into a vertical downwards flow movement and to form melt tube with a uniform circumferential wall thickness distribution.

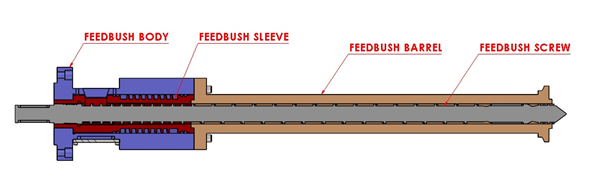

EXTRUDER WITH GROOVED FEED ZONE

Blow moulding machines with grooved barrel extruders are universal machines for all types of polyolefin; the grooved barrel system is,however, indispensable for high molecular weight, high viscosity raw materials. In these extruders, the cylinder wall in the feed section features tapered longitudinal grooves.

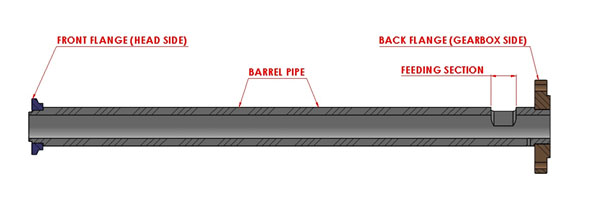

SMOOTH BORE EXTRUDER

Blow molding machines with smooth – bore extruders are more or less limited to the processing of low to medium molecular weight polyolefin types. Smooth bore extruders are less expensive than those with a grooved feed zone and show less screw wear.